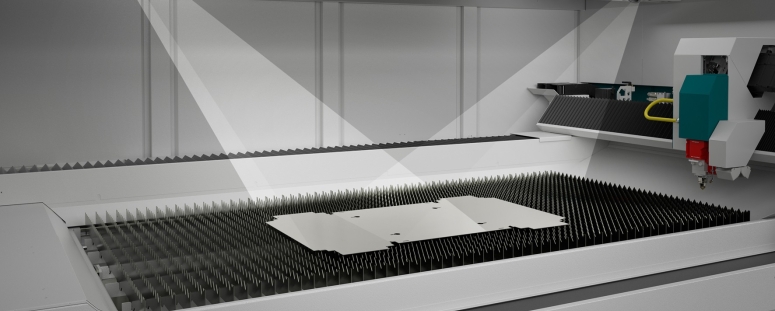

One of the clearest examples of AI’s potential in manufacturing is the adoption of artificial vision systems for laser cutting and sheet metal processing. These systems, powered by AI, have turned what were once intricate and manual operations into intuitive and streamlined processes. Artificial vision makes daily tasks faster, easier, and more accurate, minimizing the learning curve for operators and ensuring consistent results even in demanding applications.

One of the clearest examples of AI’s potential in manufacturing is the adoption of artificial vision systems for laser cutting and sheet metal processing. These systems, powered by AI, have turned what were once intricate and manual operations into intuitive and streamlined processes. Artificial vision makes daily tasks faster, easier, and more accurate, minimizing the learning curve for operators and ensuring consistent results even in demanding applications.Machine vision technology automates tasks such as aligning pre-punched or bent sheet metal and managing material waste. By interpreting visual data with remarkable precision, these systems dramatically reduce centering times and eliminate alignment errors. The impact is significant: increased production speed, optimized material usage, and reduced waste. These advances contribute not only to more efficient workflows but also to more sustainable manufacturing practices.

Moreover, AI-driven vision systems can monitor the condition of critical components, such as nozzles in laser cutting machines, detecting obstructions or wear before they affect performance. This predictive capability ensures minimal downtime, maintaining high-quality output and consistent productivity.

Waste reduction and sustainability

AI’s role in waste reduction is transformative. In sheet metal working, the efficient use of materials has always been a priority, but AI is taking it to new heights. Vision systems can identify and repurpose leftover sheet metal, automating the nesting of new parts onto residual material. This capability minimizes scrap and makes the production process significantly more sustainable.

For manufacturers, reducing waste translates directly to cost savings and environmental benefits. By optimizing the use of raw materials and reducing non-compliant parts, AI helps meet sustainability goals without compromising productivity or quality. These efficiencies are essential in today’s market, where sustainable practices are not only desirable but increasingly required by regulations and customer expectations.

The role of robotics and real-time adaptability

AI-powered vision systems are also revolutionizing robotics in manufacturing. When integrated with robots, AI allows for real-time adaptability, enabling machines to handle parts of varying shapes, sizes, and orientations without manual intervention. This flexibility is critical for tasks such as material handling and palletizing, where production requirements can change frequently.

Vision-guided robotics can identify and adjust to new specifications on the fly, allowing manufacturers to switch between different products or materials seamlessly. This adaptability reduces bottlenecks, minimizes downtime, and enhances productivity, making production lines more agile and responsive to market demands.

Empowering the workforce

The integration of AI and artificial vision is not just about automation—it’s also about empowering people. By automating repetitive, low-value tasks, these technologies free up operators to focus on higher-level responsibilities like programming, process optimization, and innovation. This shift redefines roles on the production floor, allowing workers to collaborate with machines in ways that enhance efficiency and creativity.

Rather than replacing human expertise, AI complements it, enabling operators to achieve results that were previously out of reach. As AI continues to evolve, we can expect even more opportunities for human-machine collaboration, making manufacturing environments smarter, safer, and more satisfying to work in.

A future of intelligent manufacturing

The future of AI in sheet metal working is bright. As AI becomes more sophisticated, vision systems will move from being reactive to predictive, anticipating issues before they arise and optimizing processes in real time. We also envision greater integration with emerging technologies like augmented reality and digital twins: this will further enhance these capabilities, allowing operators to visualize machine performance, diagnose issues, and simulate production scenarios with ease.

These advancements promise a new era of intelligent manufacturing, where efficiency, sustainability, and adaptability are built into every process. AI-driven vision systems are more than just tools—they are catalysts for transformation, helping manufacturers optimize resources, reduce waste, and remain competitive in an ever-evolving market.

The factories of the future won’t just produce goods—they’ll produce possibilities. And with AI and artificial vision leading the way, the potential for innovation is limitless.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Industry 4.0 Guest columns

Industry 4.0 Guest columnsThe vision revolution: how artificial intelligence is transforming sheet metal working

Published on 26/02/25