Metal-Interface recently had the privilege to sit down with Jean-Yann Julia, a representative from Techmeta, to discuss the current challenges and future prospects of the sheet metal industry. While Techmeta is not solely dedicated to this market, Julia provided valuable insights into the evolving landscape of welding technology and the potential roadblocks that lie ahead.

Recognizing the Present-Day Challenges

While Techmeta may not be the primary authority in the sheet metal industry, Julia acknowledges the challenges it faces today. The militarization and advent of new material technologies have heightened the demand for advanced welding techniques, especially for low-thickness applications and high-quality materials like titanium. The availability and sourcing of these materials is another significant concern that companies grapple with.

Techmeta's Innovative Solutions

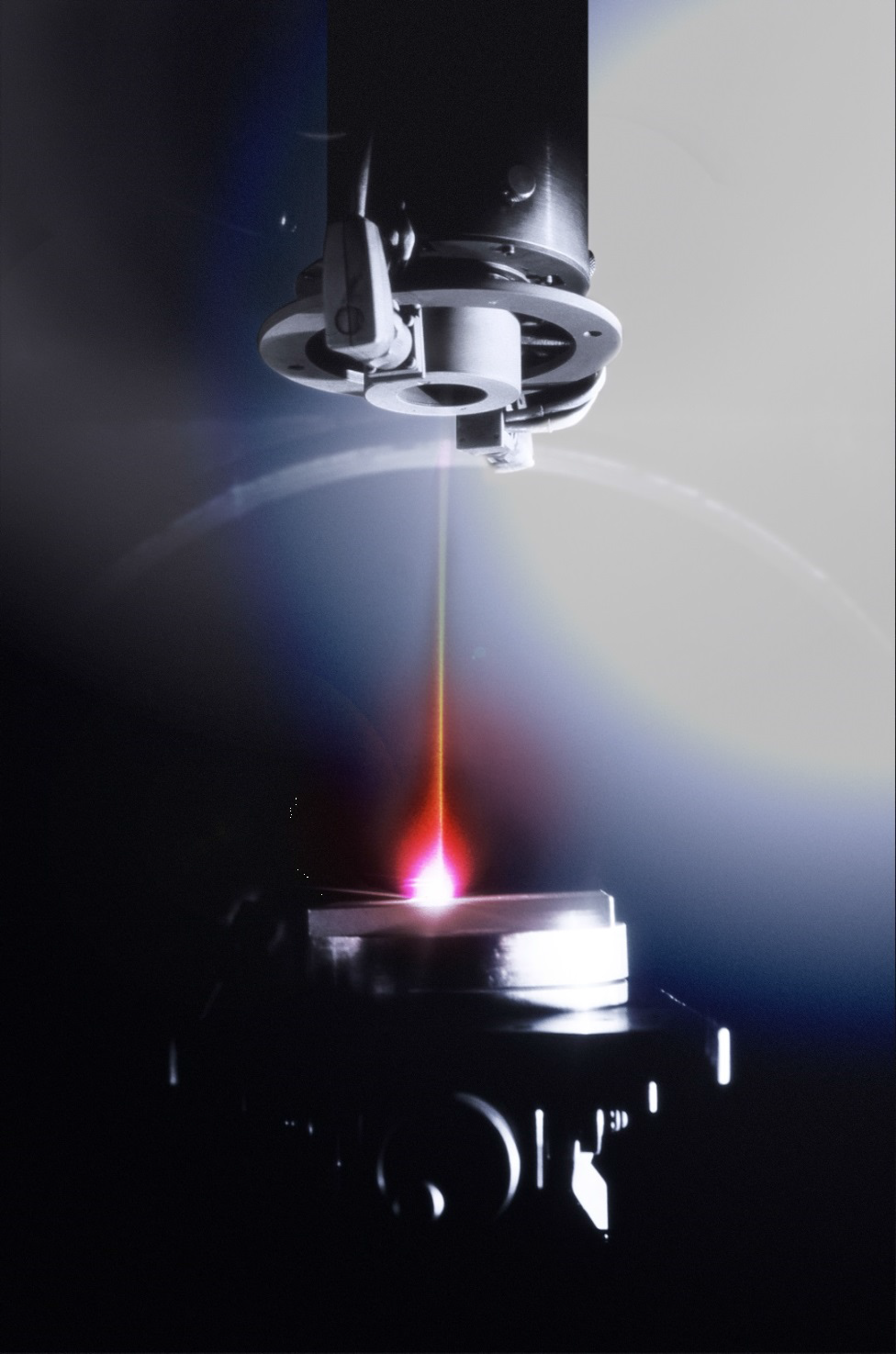

In response to these challenges, Techmeta has been proactive in developing and offering advanced solutions. Julia highlighted the company's emphasis on precision, especially when dealing with very low thickness materials. Their unique application ensures that welding is carried out accurately to prevent distortion. With this new implementation in their welding technology, they achieve high-quality results, enabling clients to use the welded parts without further adjustments. This precision not only ensures the highest quality but also minimizes waste – a crucial factor in today's environmentally-conscious world.

Anticipating Future Hurdles

When asked about potential future problems, Julia pointed towards the management of elongated parts in EV Welding. The current reliance on under-vacuum systems means that they need to evolve their technology to incorporate local vacuum systems. This would allow the placement of specific parts inside the vacuum chamber, enhancing the welding process's efficiency.

Furthermore, as industries worldwide are pushing for faster production rates, Techmeta understands the need to evolve. Julia mentioned that they constantly strive to improve their technology to keep pace with customer demands and ensure they can offer high production services.

Spotting Global Opportunities

Despite the challenges, Julia is optimistic about the future, especially with the growing trend towards electric products. Techmeta has already begun dedicating resources to this area, foreseeing the rise in electric vehicles and other similar applications. They are committed to staying at the forefront of technology and continue to innovate, offering high-production solutions that meet the demands of the modern world.

The sheet metal industry, like many others, is undergoing rapid changes driven by technological advancements and shifting market demands. Companies like Techmeta are not only acknowledging these challenges but actively working towards innovative solutions. With dedicated professionals like Jean-Yann Julia leading the way, the future of the industry looks promising. We thank Julia for his insights and look forward to seeing how Techmeta and others will shape the sheet metal industry in the years to come.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Schweissen & Schneiden 2023 Press release

Schweissen & Schneiden 2023 Press releaseFrom Material Availability to Welding Precision: Jean-Yann Julia Talks Sheet Metal Industry

Published on 03/10/23