Euroblech is one of the most important trade fairs for the machine manufacturer Lissmac with a focus on sheet metal working. This year, the company is concentrating on presenting the SBM series and the SMD 3 series. Both types of system operate highly efficiently and can be customised for a wide range of customer requirements.

Basically, Lissmac customers always have the option of choosing between two machine concepts with regard to their order processing: double-sided processing in one operation and single-sided processing - dry on one side or wet on the other.

Double-sided, dry machining offers a lot of efficiency potential

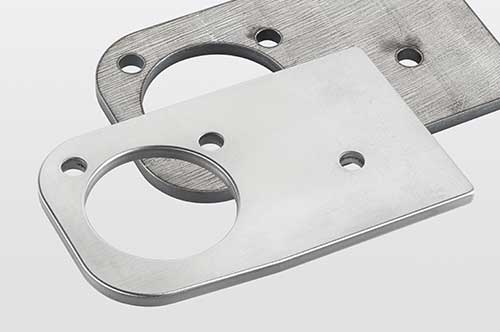

Double-sided, dry machining offers a lot of efficiency potentialIn Hanover, Lissmac will present three models of the SBM series. "These machines set standards in sheet metal processing. In the dry machining process, the efficient machin-ing of all cutting contours on both sides of sheet metal, i.e. the outer and inner contours, takes place in just one work process. Synchronous machining on both sides offers maxi-mum productivity and the best machining results," says the manufacturer.

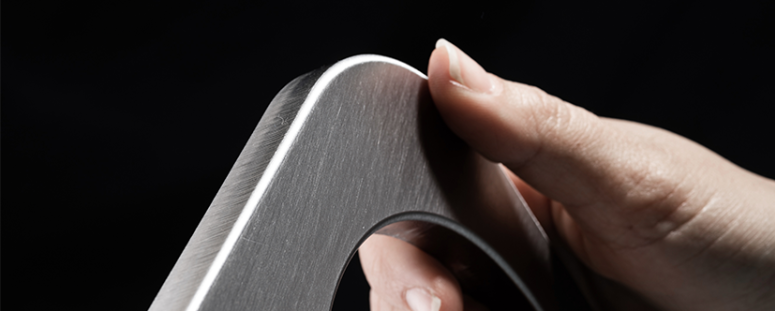

The machining principle ensures uniform tool wear across the entire working width. Moreover, the dry processing means that no chemical additives are required, as is the case with barrel finishing, for example. According to Lissmac, all machines in this series stand for energy efficiency and high and consistent machining quality. In addition, a quick and easy tool change is possible.

The Lissmac equipment portfolio comprises four machine series. Depending on the pro-duction task or sheet thickness, the SBM-XS, SBM-M, SBM-L or SBM-XL series is used. These machine models differ in terms of working width, as well as the number and type of units for workpiece machiningFully automatic small parts processing

Particularly in small parts machining, high quantities are often processed. Lissmac pre-sents its SBM-XS 300 ALU MIX small parts deburring machine with a loading robot. The line ensures a low-manpower and efficient production process through bin picking. It also features a modern, compact machine design and thus a small footprint, as well as simple and intuitive machine operation. The SBM-XS 300 ALU MIX with vacuum table is de-signed for deburring and edge rounding of steel, stainless steel and aluminium with sheet thicknesses from 1 to 15 mm and for part sizes from 45 x 45 x 1 mm up to a maxi-mum of 200 x 200 x 15 mm, depending on the geometry. . Inner and outer contours are machined equally. The integrated turning station eliminates the need for time-consuming turning and reprocessing of the parts. Folding away the turning station allows parts with an edge length of more than 200 mm to be processed unilaterally.

For deburring and edge rounding of the inner and outer contours of stamped parts of punched parts, as well as for laser- or fine plasma-cut workpieces, the two dry-operating SBM-L 1000 G1S2 and SBM-L 1500 G1S2 machines will be shown. The focus of the two systems, which are implemented with passage widths of 1000 mm and 1500 mm respec-tively, is the removal of spatter on the sheet surface. Here, too, the deburring of the often very heavy workpieces on both sides saves cost-intensive turning or machining of the parts twice. The processing units are individually electrically adjustable or can be switched on and off. The transverse machining principle ensures optimum tool utilisation over the entire working width and the modular, compact construction in modern machine design requires only a small amount of space.

Very important for the employees at the plant is the improved working environment of the plant through extraction and filter technology. This significantly reduces dust, dirt and noise pollution. Optional smart features include automatic tool wear compensation, auto-matic sheet thickness measurement, a barcode scanner and other tools.One-sided, efficient dry machining for beginners and professionals

The product range of single-sided dry grinding machines includes the particularly eco-nomical entry-level models of the SMD 1 series. Their range of applications extends from deburring and all-round edge rounding to the removal of heavy plasma or flame-cut slag.

At Euroblech, Lissmac will present the universal entry-level machine SMD 123 RE, which can be used for machining steel, stainless steel and aluminium. It is suitable for removing cutting burrs that occur during punching or laser and plasma cutting. The two rotor heads of the system enable uniform edge rounding on all sides and also a directionless finish. The creation of a surface grind is possible without time-consuming set-up work. Compo-nents can also be machined by forming. The SMD 123 RE has a small footprint and can be operated intuitively via a touch panel. Other features include separate switching on and off of the processing units, a continuously adjustable sanding belt speed and a quick and easy tool change.In the high-performance segment, the versatile models of the SMD 3 series are convinc-ing for efficient part processing from 50 x 50 mm, regardless of the part geometry. The range of applications extends from slag removal, deburring and uniform edge rounding up to a radius of 2.0 mm to surface finishing and small parts machining. "The sophisticat-ed tool arrangement of the SMD3 series ensures a uniform machining result over the en-tire working width. Maximum tool contact with the components ensures perfect edge rounding up to a radius of 2 mm. A programme memory ensures automatic machine set-ting and reproducible machining results, and a fixed machine table with constant table height ensures ergonomic working," says machine manufacturer Lissmac, summarising some of the advantages. On top of that, there is intuitive operation thanks to the clearly laid out touch panel and fast machine setting using automatic positioning of the tool ax-es. A quick tool change system reduces set-up times to a minimum and optimum accessi-bility to the machine facilitates cleaning and maintenance.

In Hanover, visitors to the Lissmac stand can find out about the SMD 345 REER (S-Edition), for example. The system can be used in a variety of ways - from edge rounding R2 to finishing. The creation of directionless grinding patterns and strong edge rounding is also made possible by several round brushes. According to LISSMAC, the machine is also predestined for processing sheet metal with coating, foiling, embossing or through-passages, the processing of various materials such as steel, stainless steel and

aluminium as well as the simultaneous machining of different material thicknesses.

The SMD 335 DRE (P-Edition), which will also be presented, is suitable for machining thick sheets. It scores with cool-grinding due to low heat input into the workpieces. Me-chanical slag removal also eliminates the need for expensive machining and results in reduced tooling costs for users. As with all systems in the SMD 3 series, LISSMAC also offers various optional features for individual customer requirements.In cooperation with the straightening technology specialists from Kohler Maschinenbau GmbH, Lissmac will also be presenting a processing line for deburring and part straight-ening in a single operation at its exhibition stand. The interlinking of the two processes ensures an efficient production process and material flow and thus significantly reduces the effort required for material handling and logistics. "The highest machining quality of the workpieces is the optimal prerequisite for further machining and processing of the components," says Lissmac.

No matter what task the companies want to solve, the Lissmac team of experts looks for-ward to individual consultations and professional exchange. Lissmac will be present at Euroblech in Hall 14 at Booth K06.Overview of the products at Euroblech:

- SBM-L G1S2:

Deburring machine for double-sided deburring and edge rounding of punched, laser and fine plasma-cut sheets in one operation - SMD 123 RE:

The grinding and deburring machine is a universal entry-level machine for removing cutting burrs from laser parts and stamped parts as well as after plasma cutting. - SMD 345 REEE - S-EDITION:

Grinding and deburring machine for the thin sheet metal sector and enables perfect edge rounding up to a radius of 2 mm. - SMD 335 DRE - P-EDITION:

Powerful machine for grinding and deburring thick sheets, for perfect contour rounding up to a radius of 2 mm. - SBM-XS 300 ALU MIX:

Especially for small parts, deburring and double-sided rounding of contours in one operation, magnetic or vacuum table.

- SBM-L G1S2:

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseLISSMAC AT THE EUROBLECH // hall 14 - stand K06

Published on 26/09/22