Expert of In-Die tapping for over 25 years. PRONIC is now your contact for the integration of value-added operations in the dies .

Expert of In-Die tapping for over 25 years. PRONIC is now your contact for the integration of value-added operations in the dies .Our team of specialists can advise and support your projects with in-die tapping operation as well as standard and non-standard insertion solution for bushings, rivets, pins, nuts, studs, etc… We also provide custom standalone tapping machine for high volume production.

Our commitment is to provide a premium service from the beginning of your project to the start of your production. Whatever is your country of operation, you will find a PRONIC specialist to assist you.

For In-Die Solutions, Think PRONIC !

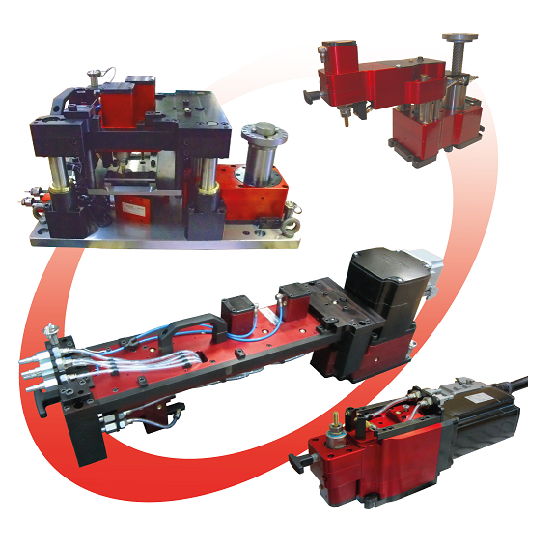

The best range of in-die tapping unit that suits all environment

For over 30 years, we do propose solutions to perform in-die tapping operations.

For over 30 years, we do propose solutions to perform in-die tapping operations.Our philosophy: Adapt all our solutions to your environment and optimise the performance of your units throughout their lifecycles.

By then, our tapping units are designed to suits your technical requirements.

Single tap ST tapping units with mechanical or servo-driven motorization embed the vertical strip movement following feature. Their easy set-up and use reduce the down-times.

The mutli-spindle TK tapping units with mechanical or servo-driven motorization are the easiest solution to transform the tapping unit into a full feature tapping station integrated into your die. The managed kinematics, they can be use in any kind of die: progressive, transfer, stand alone. The design and manufacture of the tapping station are quick and easy. The tooling costs are reduced.

You need even more ?

A complete and tailor made tapping station that embed all the side functions, dedicated to your environment with optimized die performances. That's our alternative totally dedicated to your needs.

ADVANTAGES :

- TAPPING one or several holes at a time from M0,8 to M12 (other, contact us)

- VERSATILITY with the choice of embedded functions

- REDUCE OF INVESTMENT COSTS by re-using of main assemblies (motorizations, Lubrication units by example) and simple die design.

- OPTIMIZATION OF PRESS RATES with the integrated strip piloting feature.

- INCREASED TAP LIFETIME thanks to the strip guidance, pilots and inner lubrication.

- MONITORING OF THE TAPPING TORQUE for all the servo-driven solutions (see conditions)

- REINFORCED SECURITY of the motorization and cartridges assemblies for even more production serenity.

A tailor made range for in-die insertion of component

For more than 10 years now, we've become an important contact for in-die insertion needs. Usually installed and crimp by secondary operations. Components like bushings, nuts, studs, kneeballs,... can be inserted under the press.

We propose turn-key solutions. Compossed of a distribution trolley connected to one or sevral insertion headsd installed in the die.

MAIN FEATURES:

- REDUCTION OF INVESTMENTS Trolley and heads can be shared from die to die for the same components to insert.

- USES OF STANDARD COMPONENTS just choose your favorite components supplier and we adapt or design the whole solution

- OPTIMIZATION OF PRESS RATE by using the best kinematics for your die.

- PROCESS SAFETY by sensors for the correct component installation and its quality.

- SAFETY OF USE with several sensors that monitors the trolley and insertion head before, during and after the insertion cycle.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Optimise your processes Press release

Optimise your processes Press releaseImprove your productivity and costs with in-die process

Published on 08/10/20