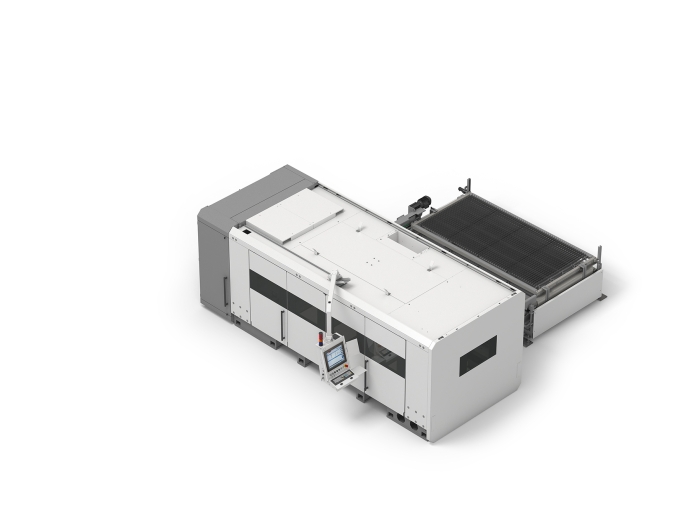

The BLM GROUP presents the laser sheet-cutting system called LS7 at EuroBLECH

The Hannover trade show is an exciting opportunity to learn about recent developments in sheet metal and see all the solutions dedicated to laser cutting

EuroBLECH 2022, in Hanover from 25 to 28 October, will be the opportunity for the BLM GROUP to present an overview of its solutions and its comprehensive portfolio of software and services. The big news concerns sheet metal laser cutting. Visitors to the show will be able to see the LS7, the latest addition to the BLM GROUP line-up resulting from the company's recent technological research, and learn more about every detail of the new system.

It's more than the LS7! Do not miss the other machines at the event!

The following machines will be on show on the BLM GROUP stands D118 (Hall 12) and E182 (Hall 13) together with the LS7.

LT8.20, the most complete Lasertube of them all

The LT8.20 is the Lasertube system equipped with a 3D laser cutting head that offers the largest working range in laser cutting of standard and special section tubes, from 12 mm to 240 mm in diameter. With the LT8.20, productivity for large and small batches is guaranteed because production changeover is automatic and only a few minutes are needed to start a new batch.

LT8.20 is the product with the largest number of configurations and loading and unloading lengths, technical solutions and options available to effectively meet a broad array of needs and specific production requirements. The layout can be decided by the customer according to the available space and, above all, to the required production type and work organisation.

The system offers consistent quality and performance over the entire range of machinable diameters, whatever the complexity of the part and cutting path, specifically with any material and thickness, with closed or open profiles, with 2D or 3D laser cutting and regardless of the number and shape of geometries.

In addition, LT8.20 can be equipped with special additional features called Active Tools for even better results, faster and regardless of operator experience. Ease of use and maintenance are the result of new proprietor technical solutions which support the operator in everyday use.

The system on show at EuroBLECH also implements a Drill&Tap device for drilling and tapping directly on the system with no need for dedicated machines. This solution ensures part precision because it avoids possible repositioning errors and eliminates intermediate handling and storage.

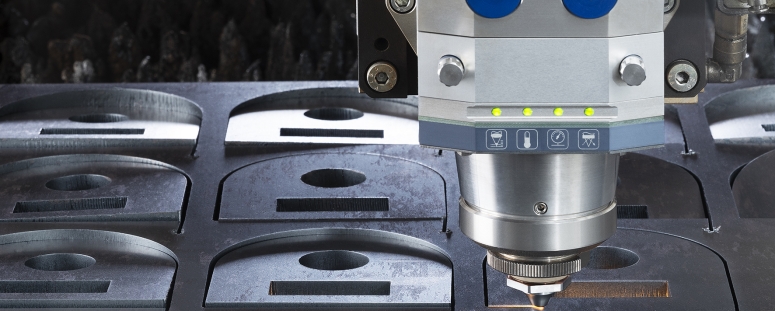

LS5, the sheet metal laser cutting, ideal for unmanned operation 24 hours a day, 7 days a weekThe LS5 is a fully automatic, flexible and productive high-end sheet laser cutting system equipped with an IPG fibre laser source of up to 12 kW and Precitec Zoom head. Extremely versatile and capable of adapting to the most diverse production requirements, the LS5 offers the possibility of adding, even after purchase, the Lasertube module for switching in zero time from laser tube cutting to sheet cutting and vice versa, and any automatic sheet loading and unloading systems and warehouse towers.

The system can be provided with all the Active Tools functions, including Active Piercing for increased cutting performance on thicker materials, Active Cool for improving the workpiece cutting quality using water, Active Camera for helping the operator to make the most of the material by managing the nesting with a simple Drag & Drop method on the screen, and Active Nozzle Changing for automatic replacing of the cutting nozzle and monitoring wear whenever it is required by a new batch.

LT360, the extremely flexible and compact robot laser cutting cell

The machine on display is designed for cutting on a fixed table and is the ideal solution for deep-drawn, flat or pressed sheets. It has a 3 kW fibre laser source and is equipped with a comprehensive technology database in addition to state-of-the-art technological features, such as Active Focus for optimising the cutting process for high quality and productivity on any type of workpiece.

The LT360 is available in various configurations. In the One Flex configuration, it is equipped with a workpiece handling robot, an ideal solution for laser cutting bent or hydroformed tubes. In the Tailored configuration, the handling robot is used to pick up the piece directly from outside the enclosure to allow integration of the cell in the most automated production contexts.

The extremely attractive price, production flexibility, configurability and experience already on the machine encapsulated in a comprehensive technology database designed to facilitate the operator's job, makes the LT360 the ideal system to enter the vast world of 3D laser part cutting applications.

BLMelements: A complete software suite for managing your processing technologiesIn parallel to laser cutting systems, BLM GROUP offers a suite of native software programs that makes the most of the power of the equipment to provide users with excellent work performance and robust process features for programming both on the machine and in the office.

VGP3D is the three-dimensional graphic programming software for BLM GROUP tube bending machines and wire benders. Simple, user-friendly and powerful, the is also available in an office version and allows the operator to create any shape or geometry with the tube with a few simple clicks.

Artube is BLM GROUP CAD/CAM software for programming Lasertube systems to allow operators to draw, manipulate and design single parts or complex tubular assemblies of any section. Artube is the most complete CAD/CAM, dynamic and adaptable to the customer’s specific needs.

ArtCut is the CAM software for programming 3D laser cutting cells for programming new parts offline and starting production quickly and easily. With its immediate and user-friendly 3D graphics, ArtCut simplifies the programming of any three-dimensional workpiece and automatically solves any collisions. The cutting program simulation is remarkably true to reality.

Partviewer runs a graphical simulation of cutting programs for Lasertube systems and estimates execution times and costs.

Protube is production MES, a single interface for easy and transparent management of part programs for the main BLM GROUP machines. Protube can be used to prepare technologically precise work orders in the office, to efficiently plan production, send production orders to the connected plants and keep track of all operations. It applies artificial intelligence strategies and data interconnection with the customer's corporate ERP. Protube is the key enabler for the evolution of smart Industry 4.0 applications.

Customer-oriented services with dedicated solutionsThe BLM GROUP can offer a wide range of services designed to accompany the customer throughout the lifecycle of the system to maintain the highest level of efficiency and machine availability.

The many services that the group offers include:

Software and remote assistance contracts for quickly resolving any unexpected problems and providing support in the event of new production needs. Remote assistance also uses augmented reality tools, like Active Eye, to quickly transmit the necessary instructions to the operator.

BLManalytics monitors machine production data in real-time to provide useful information on plant use and production, highlighting potential critical issues and possible areas for improvement to help you make quick, targeted and effective strategic decisions, ensuring maximum efficiency and reducing maintenance costs and downtime.

Various maintenance plan levels. Customers can choose the maintenance plan that best suits their production rate, plan operations so that they never interrupt production and increase the life of each machine by adopting specific activity schedules: Routine and/or supplementary maintenance and repair of faults and supply of spare parts.

Whatever the production context, the BLM GROUP has a complete range of solutions for the machining of tubes, sheet metal and any three-dimensional metal profile, enhanced by dedicated software solutions and a portfolio of services that provide customers with all-around support.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseBLM GROUP introduces the LS7 at EuroBLECH 2022, the new laser machine

Published on 07/10/22