Here we will be showing 3 checkpoints on raw material that are not to be neglected during bending, beforehand as well as during the entire production cycle.

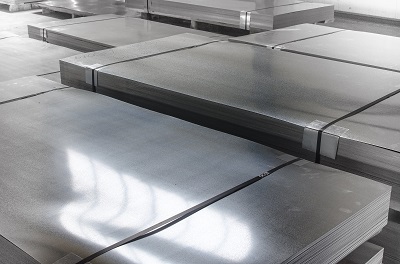

To introduce the topic, Clément Contet - Arcode points out that "the "materiel" factor plays a major role in the bending process. The material can vary greatly from one supplier to another with highly elastic materials. For example on a F355, elastic spring back can be completely different from one supplier to another, or even from one batch to another. Inspections of a same range are necessary, with inspection gauges for example. This inspection is imperative each time a batch of material is changed. »

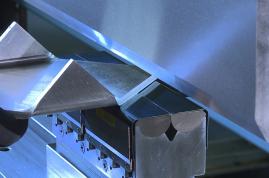

"Hot-rolled steel has a thickness tolerance range of 5%, which affects bending and gives angular deviations. The difference in thickness on the same sheet can range from 1/10th to 2/10th" explains François DEBACKER - LVD.

The material characteristics can be altered depending on the cutting technology and can impact the bending. Jean-Luc Topenot -Colly Bombled gives an example "one of our clients manufactures small brackets and small “U”. When the part is laser cut, the edge of the steel sheet is heat soaked and, when bending the part, it tends to curve. Constraints of the material related to laser cutting impact the consistency of the bending, compared to shearing for example. This phenomenon essentially impacts small parts when the bend is close to the hardened edge. »

Polishing: be careful of the impact on bending!

With materials that have special finishings, such as polished sheet metal (304L stainless steel for example), finishing defects, such as a scratch, can be corrected after cutting by polishing the piece.

The operator who sees scratches, can find himself re-polishing the part, insisting on removing the flaws. After two or three times, the part will lose a few tenths of thickness and the resistance of the material will weaken. The differences in angle can quickly be in the order of half a degree to a degree.The operator can also identify a stack of parts that have been polished several times. This is how the bending operator inspects the parts, then adjusts the bend if necessary.

Separation of material batches

The same identical material does not react consistently from one batch of material to another.

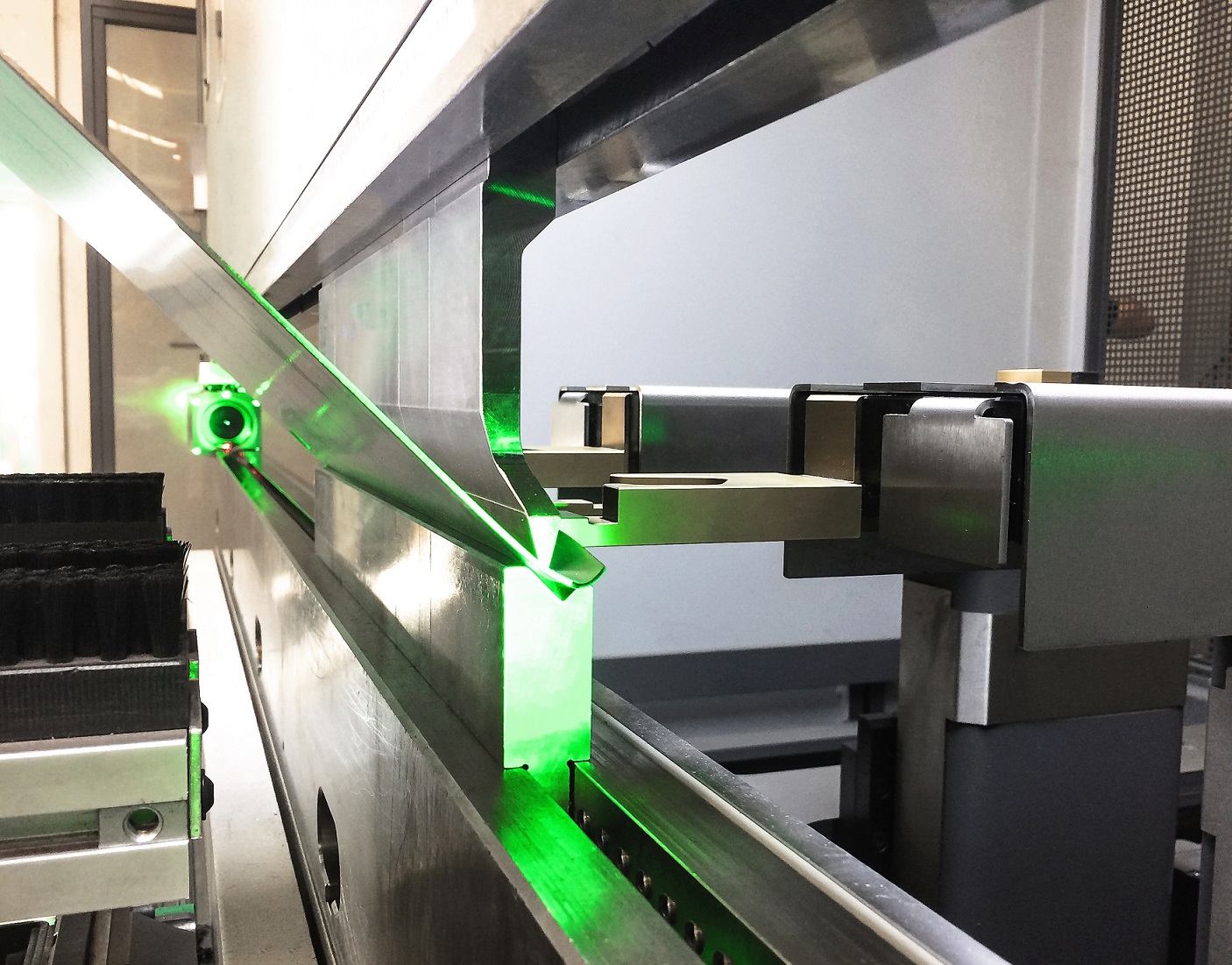

Throughout the production of a range, parts could have been cut with batches of different material. The operator can therefore indicate a change in batch of material in the stack of pieces to be folded quite simply, by adding a mere part of paper where the change in material occurs. The press brake operator can therefore pay particular attention and inspect the part to make sure "that it bends identically".Pierrick Grand - Extratole adds that "the quality of the material varies and forces us to make intermediate inspections, to check that there are no mishaps. Some materials are more subject to variations, such as aluminium for example. »

The rolling direction

The behaviour of the material will depend on the positioning of the bend to be achieved with regard to the rolling direction. This is an important aspect to take into account. Especially since the behaviour may be different on the same part, if the bends are not pointing in the same direction as the rolling direction.

See the article dedicated to this subject: Bending and material fiber: how to limit the precision impact of the bent parts?

Copyright - reproduction prohibited without written permission from Metal-Interface

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Bending dossier Technical article

Bending dossier Technical articleRaw material and bending: 3 essential inspection points