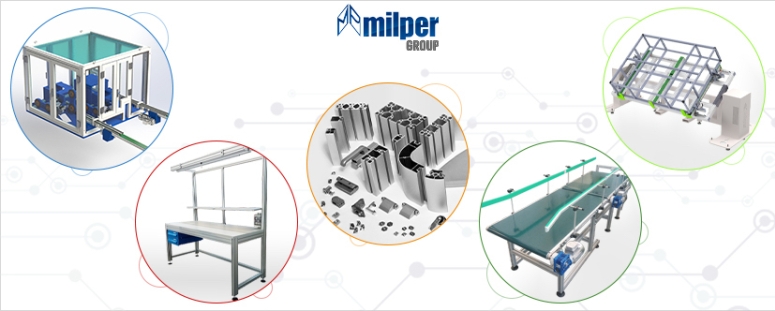

Since 1998 we have been working in the following industrial sectors: food, packaging, mechanics, textiles, marble, wood. The desire to constantly improve and develop new ideas and products has led us, over time, to build new facilities: today the Milper Group includes three production units covering a total area of 3000 square meters. Over the years we have managed to establish a relationship of mutual reliability and trust with both our suppliers and our customers. This has been a key element that has turned Milper Group into the solid company it is today. Our product range includes Aluminium profiles and tubes – Accessories – Machinery safety guards - Work benches - Conveyor belts – Pantograph elevators and tilters. A team of experienced technicians is available to study and design solutions with the customers to meet their needs.

Aluminium profiles and safety guards for industrial machinery

Aluminum profiles and aluminum tubes

- The sale of the Milper System is one of our strengths: a wide range of Aluminum Profiles and Aluminum Tubes (more than 150 profiles) and accessories (more than 1500 items) are constantly available in our stock.

- 24-hour purchasing availability from our online shop

Aluminum safety guards for industrial machines

- We have the possibility to customize your Safety Guards with innovative shapes and tailor-made elements, measurement by 3D scanner with two-tenths of a millimeter accuracy

- 3D project study using Virtual Reality to solve safety problems, compartmentation and many other impediments that prevent a correct production process.

Workbenches, conveyor belts and Pantograph elevators and tilters

Work benches

- Our work benches are height-adjustable and are equipped for logistics, assembly, packaging, screwing and general work activities. Our experience in dealing with ergonomic issues has led us to create Work Benches that are adaptable to the operator and his movements. The application fields of this product are automotive, packaging, electronics, household appliances.

- Possibility of configuring a workbench free of charge on our website 24 h/24

- Our conveyor belts are designed to handle objects or materials of different types and sizes. Our designs can be tailored to any need, according to the type of product, the speed and load weight. The sectors of use are packaging, food, pharmaceutical, textile, wood, mechanical industry, etc.

- Our R&D department has been proposing the use of ALUMINIUM profiles for the construction of heavy-duty conveyor belts for over 20 years.

- Unlike STEEL, which is commonly used for handling heavy materials, ALUMINIUM allows the construction of high-performance modular structures.

Pantograph elevators and tilters

- Our pantograph elevators/tilters are designed for loads of over 1500 kg and are manufactured by assembling pre-built modules. Providing workstations that are suitable for the operators, ergonomic and allow them to lift heavy loads safely in the various production departments is the key to keeping a company's production process running smoothly and efficiently.

- Our distinctive features are as follows:

- - Height adjustment to tenths of a millimetre accuracy

- - Total tilting up to 180°

- - Smooth micro-pulse movements with joystick operation

- - Possibility of remote connection.

Modular and mobile guards for robotic welding stations

A new solution to protect the welding station (with Milper patent) is the alternative to the curtains normally used on welding machines.

It offers several advantages: good resistance to welding sparks, possibility of replacing the aluminum sheet when damaged by sparks, possibility of replacing the polycarbonate with another panel.

The Anti-spark Guard can be supplied in a fixed or folding version:

1) transparent polycarbonate: 8 mm thick

2) 45x45 structural profile in anodized aluminum.

3) Possibility of mounting wheels for the mobile version

4) Galvanized, electro-welded mesh, 30x30 wire, 3 mm thick.

5) Floor fixing with die-cast aluminum legs

6) Anodized aluminum sheet, 2mm thick

7) Hinged mounting in the "folding" version

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

LAMIERA 2022 Press release

LAMIERA 2022 Press releaseMILPER GROUP: We have been developing innovation since 1998

Published on 15/04/22