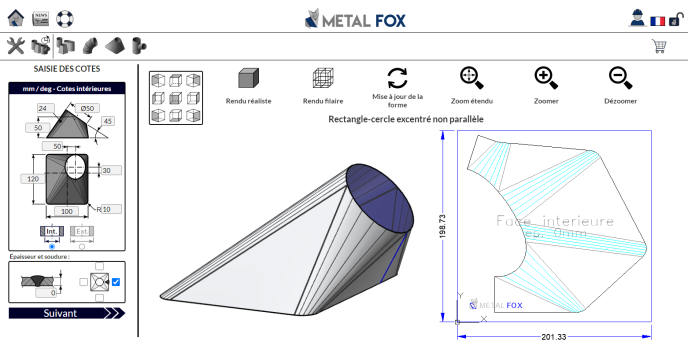

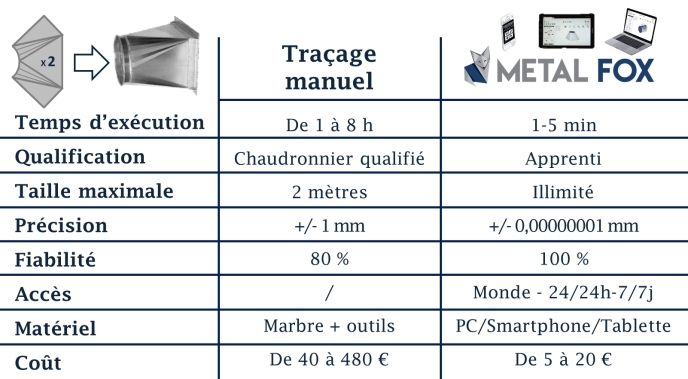

MetalFox.net is the first online sheet metal flattening software.

Accessible without installation from a web browser, MetalFox allows all professionals, even non-experts, to reliably and accurately flatten the most complex shapes in less than 5 minutes.

Adaptable to Smartphone, tablet and PC, MetalFox is used in workshops, construction sites and design offices worldwide.

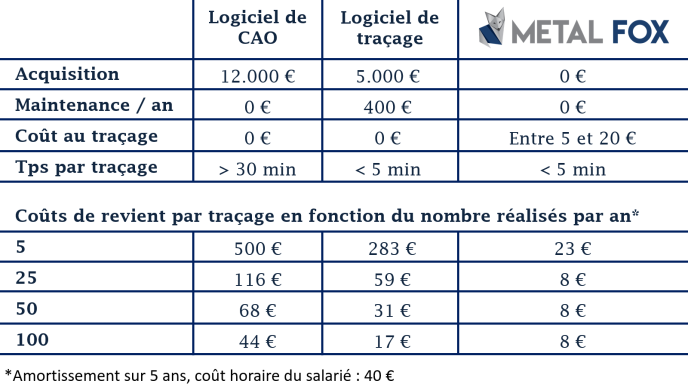

MetalFox is economical and offers purchase options adapted to the activity of companies: pay-per-use or subscriptions.

From 5€ per job.

- A vast choice of boiler making and piping shapes.

- Unprecedented technical options: taking into account welding clearances, bending radii, etc.

- Generation in less than 5 minutes of the dxf file for machine cutting; laser, water jet, etc.

- Accessible 24 hours a day, 7 days a week from the Internet, on an unlimited number of computers per company.

The creation of a MetalFox.net account allows you to create 10 shapes for free: straight cones, cylinders, ...

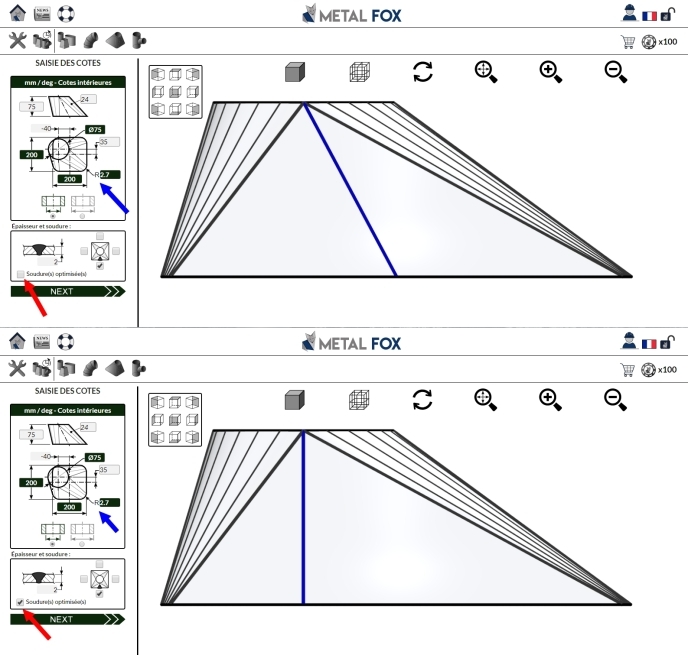

Welding optimization with MetalFox: save money and time!

Save time and money by reducing weld lengths and changing weld positions. This option is available on prisms, oblique pyramids and offseted transitions.

The aim is to save on welding costs by reducing weld lengths as much as possible, but not only …

Indeed, for some parts, such as offseted transitions, it is important to finish flat faces with a right angle.

This makes it easier the manufacturing and the assembly of the sub-parts.Why did you make this optimization optional?

Because in two cases, weld optimization could be counterproductive:

Firstly, if the part is offseted and one end of the weld is too close to the folds of the opposite section.

This will cause problems during shaping because the “triangles” of the flat parts will then be too thin. It will therefore be very difficult, and maybe impossible, to shape them properly and obtain a flat weld.Second, for aesthetic reasons.

For example for an oblique square form, placing the weld with at a right angle will create the impression of a wobbly piece.

In this case, it will then be more interesting to have a weld centered on the two opposite sections.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

LAMIERA 2022 Press release

LAMIERA 2022 Press releaseMetalFox, the online sheet metal flattening solution!

Published on 30/03/22