Bending dossier: how to meet the challenges of press brake production?

Bending dossier: how to meet the challenges of press brake production?

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Bending dossier: how to meet the challenges of press brake production?

The industrialist or subcontractor produces value when the press brake is bending parts.

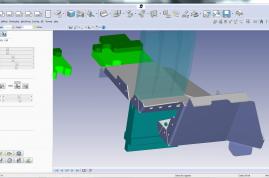

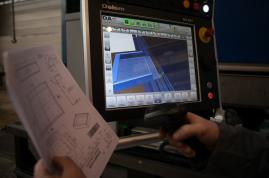

Start-up times can affect part production costs, especially small and medium-sized series

Gérard Boudesocque - AMADA introduces this topic. "Manufacturers have great difficulty finding skilled manpower, especially bending operators.

The causes of discarded parts give an interesting indication of the points to focus on with regards to the bending stations and the actions to be implemented to limit them.

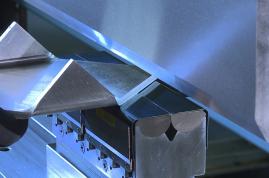

A special bending tool is highly relevant in the context of recurring manufacturing or large batches of parts.

Crowning is a distortion of the ram and the bed, induced during the bending operation by the force of the table.

Changing the tools on press brakes is an important approach for improving productivity.

The choice of the tools, their maintenance and their proper use are important elements in the precision of the parts, in the management of the press brake and for the operator.

The material characteristics are different depending on the rolling direction. The material does not react in the same way if the part is bent in the grain direction, or perpendicularly.