Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

With a constantly growing export index both in the domestic and international markets and a continuous attention to new technologies for industrial automation, OMERA has been a leading player in the sheet metal deformation sector since 1951 with the production of mechanical and hydraulic presses, trimming machines and turnkey production lines.

FAR s.r.l. for over 60 years is leader in the manufacture of a wide range of high-technology articles for fastening, to ensure maximum performances in terms of quality and service, all strictly produced in Bologna:

We are ready to welcome customers to Tolexpo, an international showcase where we will be able to present our wide range of products and innovative solutions fully equipped to meet the growing market needs.

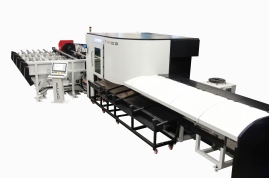

Since 1977 OMP has been a global partner for the entire tube and solid bar manufacturing process, from laser or disc cutting, to beam forming, to finishing with deburring, chamfering and threading lines. We also manufacture special machines tailored to the customer.

VICLA is the first Italian company to have believed in the potential of hybrid technology applied to sheet metal working. Always a pioneer of new technologies and innovations, the company stands out for its quality, tailoring approach and continuous innovation.

The AFUludine solution is a patented French innovation that is part of an ecological approach. An alternative to petroleum products that makes it possible to meet the challenges of our planet and anticipate future environmental restrictions. The choice of a high-performance product for manufacturers. We want to offer manufacturers ecological lubricants intended for the problem of "shaping metallic materials" to eliminate the degreasing phase. This allows our customers to reduce their costs by limiting their water and electricity consumption and thus being more environmentally friendly.

SAVIM EUROPE boasts a multi-year experience in the design and installation of industrial painting plants, both liquid and powder, customized according to the space, production and customer’s needs.The company located in Verona has always set itself the goal of being a technological partner for its customers and not just a simple supplier. This attitude has continued over the years and it is at the basis of the company philosophy.

Savim was founded in 1984 and has always aimed to expand and

Since 1998 we have been working in the following industrial sectors: food, packaging, mechanics, textiles, marble, wood. The desire to constantly improve and develop new ideas and products has led us, over time, to build new facilities: today the Milper Group includes three production units covering a total area of 3000 square meters. O

Coral IperJet DF is a horizontal cartridge filter, designed and built to extract and filter welding fumes, thick and fine dust, modest quantities of wood chips and fumes from thermal and laser cutting (in the case of the IperJet DF Thermal Cut model) with maximum efficiency. It adapts perfectly to all indoor environments and, thanks to its compact size and ease of movement, even in smaller ones.