The European metal industry is grappling with a myriad of challenges. Metal-Interface had the privilege of interviewing *Pedro Pereira from MOTOFIL, a company that is paving the way with innovative solutions for the European metal industry.

*(Pedro Pereira is the Responsible for the Exhibitions and part of the Marketing and Communication Department)

Dependence on external outsources

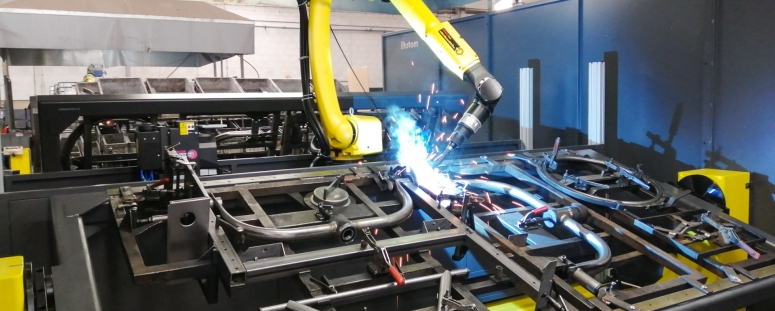

Many businesses are looking to automate and robotize their factories but find mostly local suppliers with limited capacity, that need to outsource production and equipments. In contrast, at MOTOFIL, everything is produced in-house, with solutions entirely designed and manufactured in Portugal with the integration of top European (such as Siemens automation and Fronius/Kemppi/LORCH power sources) and Japanese components brands (such as FANUC robots).

Energy

A Significant Challenge: Energy dependence, especially on Russia, stands out as another hurdle for Europe. While Portugal might not feel this dependence as acutely due to its alternative sources, countries like Germany are heavily reliant on Russian gas. Pedro emphasizes the importance of green energies as a solution to this issue. MOTOFIL also offers solutions for the energy sector, especially in the wind energy domain.

Over 40 Years of Expertise Serving the Industry

With over four decades of experience, MOTOFIL positions itself as a cornerstone of the metal industry, providing technological solutions to strengthen and rejuvenate the sector. For Pedro, challenges aren't roadblocks but daily opportunities. MOTOFIL strives to deliver solutions rather than dwelling on problems.

European Quality vs. Price

A common criticism faced by European manufacturers is the high cost of production compared to Asian markets. Addressing this, Pedro states that while MOTOFIL might be slightly more expensive, they uphold European quality standards. They ensure top-notch quality control, adhering to European regulations. Moreover, the company boasts a robust technical team, ready to assist clients whenever required. For MOTOFIL, the primary focus is on trustworthy technology combined with quality, ensuring that customers receive value for their money.

Innovative Offerings and the Future

MOTOFIL is not just resting on its laurels. They are constantly keeping an eye on innovations. Their welding systems are among the top in the market, and while they have been in the welding domain for a long time, their cutting systems are also making a mark. Furthermore, recognizing the future of green energy, MOTOFIL is heavily invested in the wind energy business, offering solutions for offshore and onshore wind industry (wind towers, monopiles, flange machining and more). Pedro believes that for a sustainable future for the coming generations, investments in green solutions are crucial.

Conclusion

In a world where industries constantly evolve, companies like MOTOFIL are a beacon for the European metal industry. With a focus on quality, innovation, and European independence, they are setting the stage for a brighter and more sustainable industrial future in Europe. As Pedro Pereira rightly points out, challenges are just daily opportunities in disguise, and with the right solutions, the future looks promising.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Schweissen & Schneiden 2023 Press release

Schweissen & Schneiden 2023 Press releaseNavigating the challenges of metal automation and green energy: A deep dive with Pedro Pereira of MOTOFIL

Published on 10/10/23