Castellanos y Echevarría –Vitoria SA, a company based in Vitoria-Gasteiz, has been offering industrial weld preparation solutions since 1969. The production is dedicated to the niche of chamfering solutions for sectors such as construction, boiler construction, shipping and defense industry, energy and transport under the CEVISA brand and is market leader in the industry.

CEVISA designs and manufactures self-feed bevelers for plates and tubes, mainly used in steel working industries and welding activities.

As a Pioneer in automated bevelers, CEVISA succeeds in manufacturing high performance bevelling machines, reliable and fast to optimize times and costs production. They work tirelessly to develop innovative bevellers to meet requirements for the most demanding sectors.

CEVISA has a proud 50 year history as a global manufacturer, working and growing hand inhand together with our customers. Thanks to their know-how and innovative profile, they provide efficient and customized bevelling solutions to any kind of steel sector and specialized distributor.

Today, thanks to its customer-focused value, innovative solutions (i+I+D department), and high quality standards, they are the worldwide Nº1 producer, exporting 80 % of our production. More than 60 countries work with Cevisa.

A team of engineers strive to meet the needs of its customers and offer comprehensive solutions in every country in the world where they are requested. "We grow with the needs of our customers, so we aim to respond to all special requests."

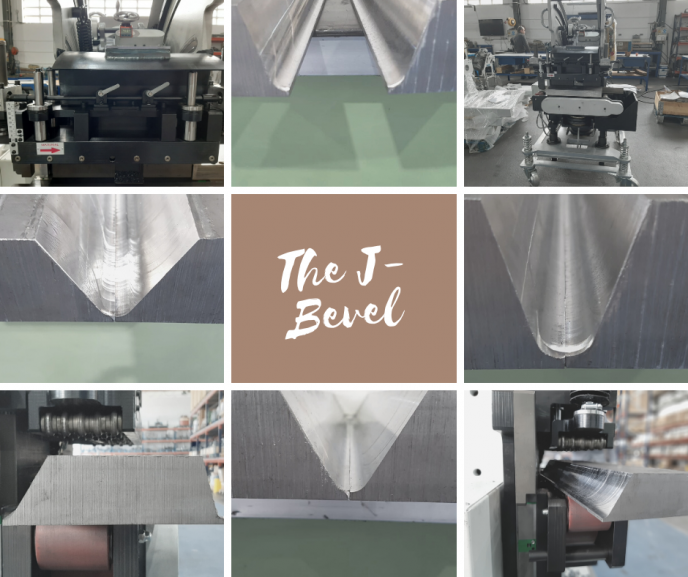

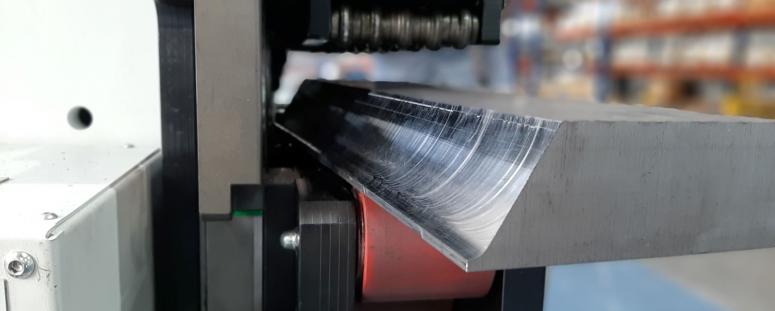

In view of the growing demand for a solution for the finishing of J-chamfers, the technical team from Castellanos y Echevarría - Vitoria, S.A. got to work. The device is already a reality and tests with the specific requirements of a customer have been successfully completed with a prototype.

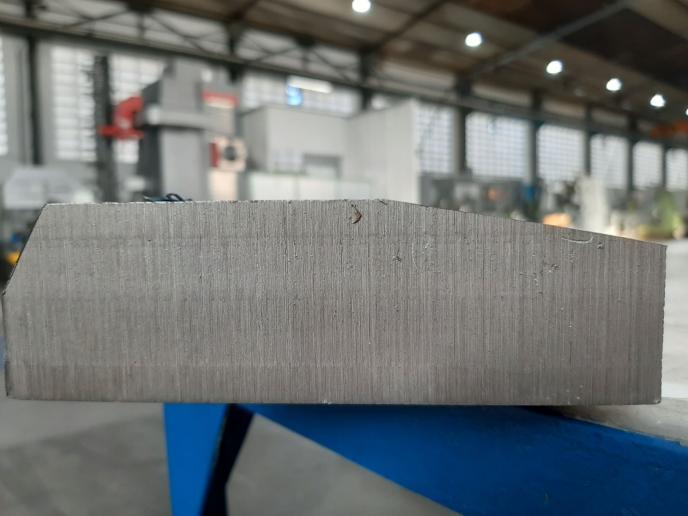

The chamfer radius only is applied in J-chamfer or U-chamfer welds. A configuration of a J-bevel or U-bevel weld is usually indicated by a bevel angle and a bevel radius. The CEVISA device offers a constant and unchangeable radius of 8 mm.The welding designer can choose the one that best suits his needs. Various connection geometries and weld seam types are available. The selection is usually based on considerations such as:

• Accessibility to the welded joint

• Appropriateness for the design of the structure.

• welding costsCEVISA will welcome you at Hall 11 Stand G127, come to vistit us!

CEVISA’S BEVELLING MACHINE CHP-60 G ADAPTED TO CUSTOMER NEEDS

Although the company was originally founded as a contract manufacturing company and is still a supplier to leading companies such as Navantia, the company has specialized in the development and manufacturing of bevelling machines under its CEVISA brand.

The company counts on a professional multidisciplinary team of engineers and technicians to respond to all kinds of industrial challenges and to offer a targeted solution in every country in the world where they are required.

"We grow with the needs of our customers, so we have set ourselves the goal of studying all special requests."

Bevelling machine with a machined finish: the CHP 60G

In the product offer of CEVISA bevelling machines, the he range of bevelling-milling machines is the latest. This series of high-performance machines currently consists of CHP 60G and CHP 60 G INV and other components for creating J-bevels that will see the light of day in the coming months.

Although our portable milling machine CHP 60 G already has on the market unique features, we have made a special machine for a customer who wants to chamfer at an angle of 20 ° to 80 °.

"More than 50 years of experience and a multitude of options are responsible for the success of the CEVISA machines that we wanted to count on with us," says the customer.

Concretely the customer has purchased a special CHP 60G, a chamfering machine with a mechanized finish, with which they can produce their 80 ° and 52 mm long chamfers in one pass for the production of loading docks with Checker plates (diamond plates). An application that has sparked the sector's interest, not using the bevel as a weld preparation. There are already further inquiries from England.

CEVISA LAUNCHES ITS NEW CHP 60G INV BEVELLING MACHINE ON THE MARKET

The spanish company Castellanos y Echevarria - Vitoria, S.A. continues the development of its chamfering program with the commercialization of its new CHP 60 G INV bevelling machine. A highly expected machine that complements the range of machines by milling. A prototype of the machine was already presented at the last edition of the Blechexpo 2019 to the delight of visitors to the CEVISA stand.

Launch of the new portable milling machine for chamfering. The fairs are a great opportunity to present novelties so we decided to make known worldwide the new CHP 60G INV bevelling machine during the last BLECHEXPO 2019 held in Stuttgart in November 2019. The prototype aroused much curiosity among visitors of the fair at the German country and the result of the demonstrations impressed the professionals of the sector. The new CEVISA CHP 60 G INV chamfering machine is yet another step in order to complete the range of bevelling machines with a milled finish. The portable milling machine has been developed to make lower chamfers in sheets with large thicknesses, very resistant materials such as Hardox or Duplex and obtaining a machined finish. This machine can make chamfers up to 60mm in length on sheets with thickness ranging from 4mm. up to 100mm. The CHP 60G INV bevelling machine is perfectly integrated into the program with the CHP 60G, a very successful machine among our customers and with the same benefits, only it performs bevels on the upper part of the sheet. The launch of the new machine has been in high demand among our customers, since between the two they achieve a perfect symbiosis: working with the two sister machines allows bevels to be made in K and X without turning the sheets and doubling the production with a single operator. Some of our clients have already been able to test the new machine at their facilities and are delighted with the time savings and therefore in production costs of over 50%.

Technical data:

- For plate thicknesses from 10 mm to 100 mm *

- 60 mm chamfer length

- Milling finish

- Advance and r.p.m. adjustable according to material needs

- 4 bar pneumatic fixing system

- uniform finish, vibration-free and low-noise

- Mobile and fix

- Adjustable working height with pneumatic lifting system

- Maximum bevel in one pass 28 mm

- Recommended maximum bevel in several passes: 60 mm

- Variable angle from 15º-70º.

Our bevelling machine CHP 12 is still our Bestseller

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Optimise your processes Press release

Optimise your processes Press releaseCEVISA CONTINUES INNOVATING: THE J-BEVEL for the bevelling machine CHP 60G

Published on 30/06/20