Schuler offers customized cutting-edge technology in all areas of forming—from the networked press to press shop planning. In addition to presses, our products include automation, dies, process know-how and service for the entire metalworking industry. Schuler's Digital Suite brings together solutions for networking forming technology and is continuously being developed to further improve line productivity and availability. Our customers include automotive manufacturers and suppliers, as well as companies in the forging, household appliance and electrical industries. Presses from the Schuler Group mint coins for more than 180 countries. Founded in 1839 at our headquarters in Göppingen, Germany, Schuler has approx. 5 000 employees at production sites in Europe, China and the Americas, as well as service companies in more than 40 countries. The company is part of the international technology group ANDRITZ.

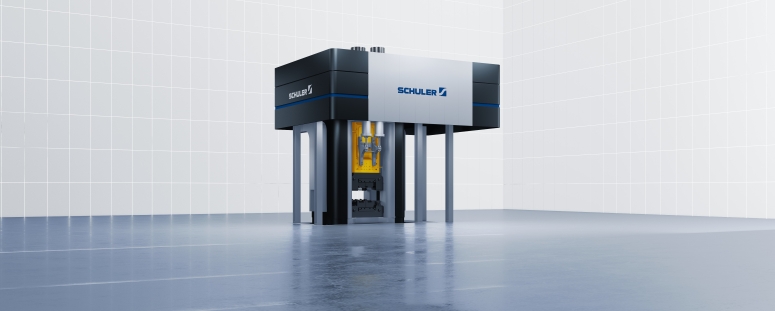

6,400 ton capacity system with energy accumulator replaces 1989 model

At its location in the French town of Châteubriant on the Atlantic coast, the agricultural equipment manufacturer KUHN develops and manufactures, amongst other things, tillage equipment, plows, and sowing machines. From the very start, KUHN HUARD has had an undeniable competitive advantage thanks to its forging and heat treatment know-how. Since 1989, the company has been using a 5,400 ton capacity machine from Müller Weingarten to produce its parts. The time has now come to have it replaced.

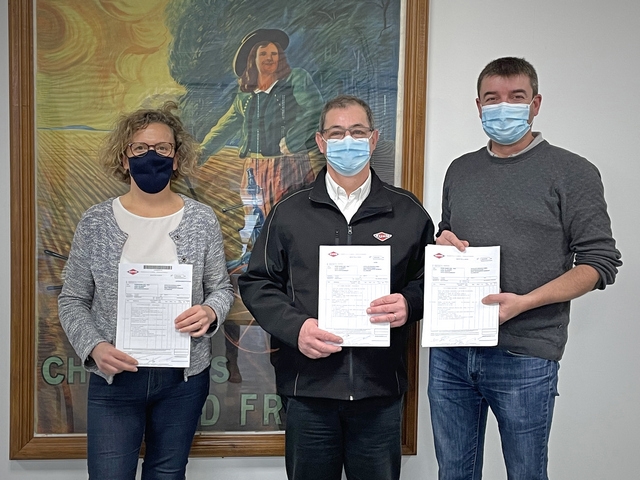

Nathalie Bessin, Pierre Yves Porcher and Charles Perrier “Our objective is to maintain our competitive advantage over the long term,” says the project team at Kuhn consisting of Nathalie Bessin, Pierre Yves Porcher and Charles Perrier. “This innovative technology will help us retain our leading position in the market.” The three quickly came to the conclusion that an investment in a new press could pay off. After one and a half years of research, KUHN has now taken a major step and placed an order with Schuler for a 6,400 ton screw press with ServoDirect technology and energy accumulator.

The new system will replace a 5,400 ton capacity machine from Müller Weingarten Screw presses have advanced a lot over the past three decades. Instead of the previously used squirrel cage induction drives, Schuler now utilizes servomotors, thereby significantly increasing efficiency. In addition, the controllability of the drive and thus the precision of the press has been improved. The closed water cooling system in combination with the new motor generation optimizes the temperature stability of the drive system, independent of the surrounding conditions.

Further included in the scope of delivery is an energy accumulator, which increases the efficiency of the system even more. Commissioning is scheduled for mid-2023.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Global-Industrie 2022 Press release

Global-Industrie 2022 Press releaseAgricultural equipment manufacturer orders screw press

Published on 29/03/22