Since it has been launched, the HDX has always combined fast machining with energy efficiency.

In a context of soaring electricity prices, the 22’ version remains the most energy-efficient machine in its category, with an installed power 50% lower on average than its competitors, for equivalent or even better performances.

Vernet Behringer's use of high performance 6-pole spindle motors combined with a 1:2 gear ratio between motors and drilling spindles allowing very high spindle torque with less power.

Moreover, the latest generation of HDX is equipped with a new servo-driven hydraulic unit: thanks to this control, the unit is activated only during some operating phases (clamping of vices, etc.) and is put on standby when hydraulic power is no longer required. In addition, it saves 80 L of oil compared to the old version and offers a much more silent operation.

The “smart motion management” technology also allows substantial energy savings, by cutting off the power supply to unused axes and motors (carriage axis during sawing operation, for example), axes being held in position by a mechanical brake. In addition, an "eco" mode reduces axis movement and machining speeds during lower workshop loads, saving energy and reducing machine and tool wear.

Vernet Behringer machines are built to last: more than 80% of 30+ years old equipment are still in operation!

However, technology is evolving rapidly, leading to accelerated obsolescence of electrical and automation parts of machines. Vernet Behringer offers retrofits to extend machine life and optimal repairability by replacing obsolete components with the latest technologies.

As a result, Vernet Behringer machines are highly sought after on the second-hand market, with a higher remaining value for sellers.

Icing on the cake: the HDX is manufactured in Dijon with an eco-responsible sourcing approach.

90% in value of purchased components come from suppliers located in France or in neighboring countries, of which 45% from local companies.

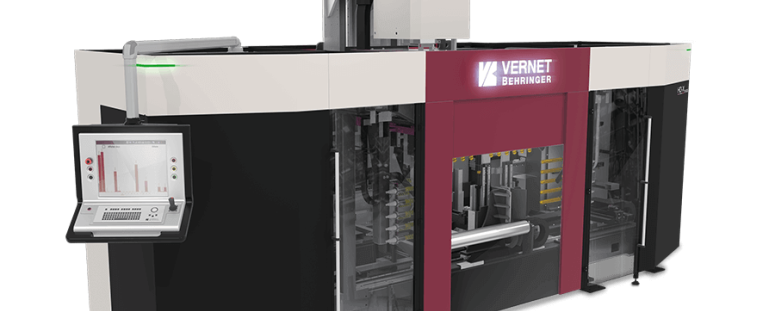

New machine name and new features for the Vernet Behringer HDX

Introduced in 2011, the HD-X has become the reference machine in its field, in particular thanks, to its 3 drilling units with 500 mm independent complementary X-axes offering unbeatable productivity in drilling, marking and milling and to its automation possibilities allowing machine working without operator.

Over the years, the HD-XEVO and then HD-XEVO2 upgrades have gained in performance and machining possibilities.

In order to simplify and standardize its range, the latest version is naturally renamed HDX!

This is accompanied by a reworked visual identity and new features:

- New notching cycles through milling with or without optimized attachments with 16 mm φ high performance VBmill carbide mills, generating a drop in machining times of up to 70%!

- New eco-efficient servo-driven hydraulic unit with intelligent control

- New ergonomic control panel with XXL 24'' touch screen, allowing a more user-friendly operation of the machine

These new features reinforce the unrivalled versatility and performance of the HDX.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseEnergy efficiency and unequaled service life for the new HDX

Published on 06/10/22