The North German software company SPI GmbH has been developing software solutions for the sheet metal industry for over 40 years.

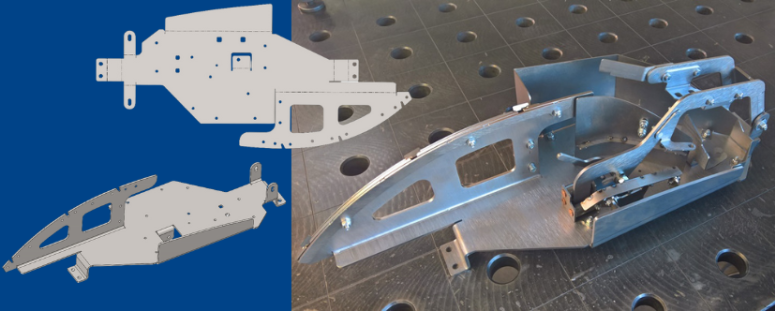

SPI SheetMetal Solutions aims to assist sheet metal fabricators and sheet metal service providers in achieving a streamlined process chain from the idea to the finished product. The software expands the sheet metal functionality of CAD applications with tried-and-tested features that save time, reduce errors, and connect design and fabrication.

The company’s experienced CAD software developers provide solutions that optimally support their customers' processes. Laser cutting, tube lasering, bending, folding, and more: no matter which fabrication methods are used, the SPI software ensures a manufacturing-ready design and flat pattern.

SPI's development partners include Solidworks and Autodesk and the TRUMPF Group.

SPI software is used on around 5000 workplaces worldwide.

Sheet Metal Add-Ins for Solidworks and Autodesk Inventor

Expand the sheet metal functionality of your CAD software:

- SPI SheetMetalWorks for Solidworks users

- SPI SheetMetal Inventor for Autodesk Inventor users

These add-ins are fully integrated into the basis CAD programs and provide a range of tried-and-tested sheet metal features that save time, reduce errors, and optimally connect design and fabrication.

The SPI software ensures that material, tool, and machine data are considered already during the design phase. An editable material and tool database works behind the scenes to ensure that the part is manufacturable with the chosen material and on the selected machines. SPI SheetMetal also includes an extensive component library that supports customers in the design of standard parts.

Correspondingly, the powerful SPI unfolding algorithm considers not only the material and sheet thickness but also the laser, punching, and bending machines that will be used to manufacture the sheet metal part. These factors flow into calculations, e.g., for bend deductions and bend radii. This ensures that even highly complex designs can be easily unfolded and that the flat pattern is ready for manufacturing with minimal pre-production work. SPI SheetMetal software accurately unfolds even freeform surfaces, transitions, curved surfaces, and other complex parts.

The functionality of the SPI SheetMetal software can be further expanded with CAM interface add-ons that ensure the transfer of all manufacturing data that each system can process:

- TRUMP Interface

- Bystronic Interface

- LVD Interface

- Schröder Interface

Furthermore, the SheetMetal Calculator add-on expands the software with a rule-based calculation functionality. It enables customers to evaluate the cost impact of design decisions, as well as to explore alternatives. The rule sets are individually definable and include manufacturing facilities, material information, labor expenditures, fixed costs, surcharges, and more.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseSPI SheetMetal Solutions - Software that Connects CAD and CAM

Published on 14/09/22