Novarc Technologies stands as an industry titan in the realm of robotic welding technology. Earning recognition on the Financial Times' fastest-growing companies list, the company has etched its mark on the global stage.

Flagship Product: SWR™

The Spool Welding Robot (SWR™) is Novarc's crown jewel. This state-of-the-art pipe welding machine offers unparalleled productivity enhancements:

- Boosts production by up to 12x for stainless steel.

- Enhances production by up to 5x for carbon steel.

Global Footprint

In collaboration with ABICOR BINZEL, Novarc has expanded its wings, exporting to an impressive roster of 38 countries. From Europe and Africa to Asia and Australia, the company's influence is truly global.

SWR™ Features

The SWR™ isn't just another robot; it's a revolution in welding:

- Capable of welding pipe spools up to 30 ft long in various positions.

- Incorporates mechanized motion for increased weld cleanliness.

- Boasts a built-in safety system, doing away with the need for hard fencing.

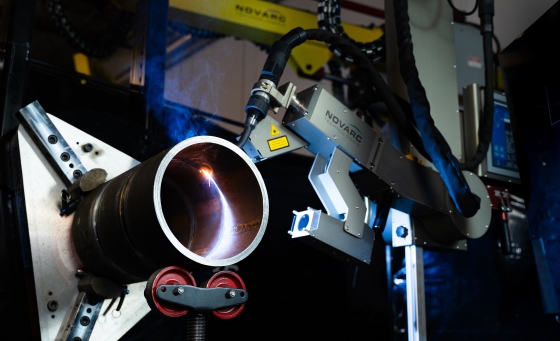

- Employs laser-assisted distance control and seam tracking for joint tracking.

- Designed with a minimal shop footprint but is versatile enough to accommodate bustling shop traffic.

Value Proposition

For fabricators, the SWR™ presents a golden opportunity to modernize operations, increase capacity, and address the skilled labor shortage. With the SWR™ system, a return on investment in under a year is not just a promise—it's a reality.

Future Vision & Mission

Novarc isn't just about today; it's about the future of welding:

- Vision: Pioneering the innovation of AI and Automation in welding.

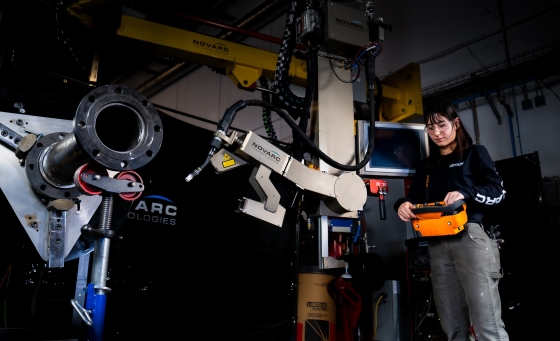

- Mission: Crafting intelligent welding cobots that seamlessly collaborate with humans to automate some of the world's most challenging welding tasks.

The World's First Collaborative Welding Robot

The Spool Welding Robot (SWR™) is a collaborative welding robot specifically designed for pipe, small pressure vessel, and other types of roll welding. Companies that have integrated the SWR™ have seen their pipe welding productivity skyrocket. The benefits include:

- Boosted pipe welding productivity to 200-350 diameter inches per shift on carbon steel pipes.

- Achieved 569-998 diameter inches per shift on stainless steel.

- Reduced repair rate to less than 1%.

Such enhancements make our customers more competitive in their bidding processes and yield higher margins on secured contracts. Furthermore, the SWR™ boasts the smallest industry footprint, and when coupled with our proprietary Welding Vision System and insights from NovData™, users are provided with a top-tier solution that significantly boosts their market competitiveness.

Key Features

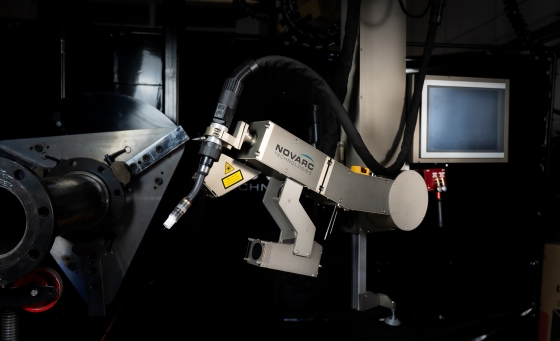

- Pneumatic Manipulator with Adjustable Height: Allows for easy arm movement between joints within a 15 ft radius. Suitable for pipes ranging from 2” to 60” at variable heights.

- Compact Design: Requires only a 1.6” clearance around the pipe.

- User-Friendly Interface (HMI): Enables operators to select pre-programmed welding procedures, adjust weld and motion parameters, and access pass tracking features.

- Advanced Hardware: Includes a durable pendant, point laser, camera for real-time seam tracking, a three-axis robotic arm, and multiple power source options.

Advantages

- Productivity improvements by 3-5x for carbon steel and up to 12x for stainless steel.

- Remarkably low repair rates of less than 1%.

- Average Return on Investment (ROI) between 6-18 months.

- Enhanced accountability and traceability through the Welding Vision System.

- Access to detailed operational reports via NovData™.

- Prolonged careers for welders due to reduced physical strain.

Testimonials

David Ray, a Fabrication Shop Superintendent at W.W. GAY Mechanical Inc., attests to the efficiency of the SWR™, emphasizing the drastic reduction in time taken for certain welding tasks. Other customer experiences can be explored in our detailed case studies.

Overview

SWR™+HyperFill® represents a revolutionary step for companies aiming to outpace their competitors. This high-efficiency, fully integrated dual torch system, which utilizes Lincoln Electric’s HyperFill® technology, maximizes productivity and profitability.

Benefits

- Weld thicker materials faster with deposition rates of 15lbs/hour or higher on fill and cap passes.

- Flexibility in welding processes, with the ability to switch between GMAW or MCAW for different passes.

- Maintain all the foundational benefits of the basic SWR™, such as a compact footprint, seamless integration with up to 5 positioners, and enhanced tracking capabilities.

Master Your Production with Advanced Analytics

NovSync™ offers a comprehensive dashboard that tracks production and machine trends over time. It provides centralized and secure access to weld videos, daily reports, and NovData™ logs, ensuring that businesses have all the insights they need to optimize their welding operations.

Why Choose NovSync™?

- Cloud Backup: Secure storage with easy, anytime access.

- SWR Analytics: Gain insights into usage and production statistics.

- Machine Health: Get early notifications to avoid production disruptions.

- Custom Reporting: Tailor reports to your specific business needs.

- Visualizations: Stay informed with clear, up-to-date production metrics.

Various plans are available to cater to different business needs, from the Lite package for smaller operations to the Essential package for more comprehensive requirements.