Bending automation, laser automation, a new laser cutter configuration system, electric bending, software, services and sustainability – these are the Bystronic highlights at EuroBLECH 2024 from October 22 to 25 in Hanover/Germany.

Niederönz/Hanover, in September, 2024 – Bystronic's primary goal is to always offer customers solutions that help them to stay ahead of the competition on a daily basis. This includes state-of-the-art machines, tailor-made automation solutions, process-optimizing software and first-class service.

Bystronic will be presenting these highlights this year: high-performance laser cutting and bending cells that ensure the competitiveness of customers thanks to the perfect interaction of various systems. This is precisely why Bystronic is focusing on automation this year.

Bending automation

Bystronic presents the ByCell Bend Star M, the bending cell with the ByBend Star 120 press brake for small and medium-sized parts, thus closing a gap. With its high performance and compact dimensions, it fits into practically any production hall.

This brand new, fully automatic bending cell with the "Optical Part Detection" function offers small and large production companies’ maximum efficiency and flexibility in bending. The ByCell Bend Star M is ideal for processing job lists as well as for changing orders – from small batch sizes to large series. In combination with the new ByBend Star 120, the agile robot completes bending jobs fully automatically and error-free.

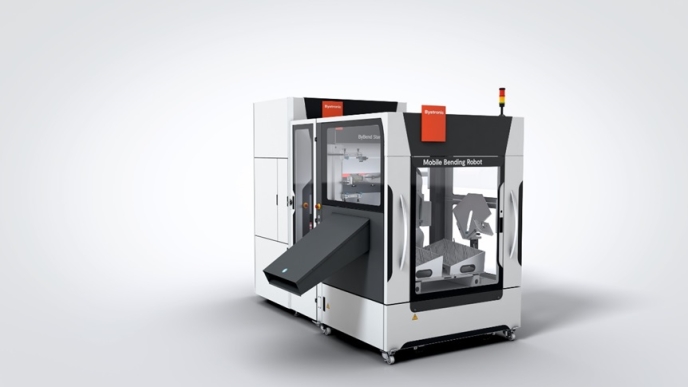

Mobile Bending Cell

If you need a bending cell in the smallest of spaces, you can rely on the Mobile Bending Cell 80, which develops a press force of up to 80 tons over a bending length of around 1.5 meters. This is made possible by the powerful ByBend Star 80 press brake, which can be easily upgraded to a fully automated Mobile Bending Cell if you already have a manual press. The Mobile Bending Robot is simply docked onto the ByBend Star and connected and referenced within ten minutes.

Laser automation

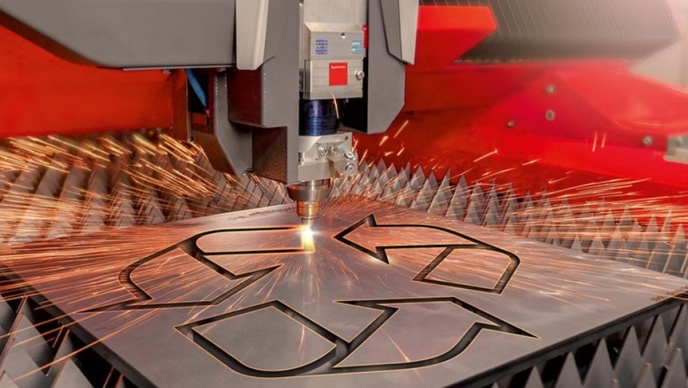

Bystronic has the right solution for entry into laser automation: the ByCut Eco laser cutter in combination with the ByLoader Flex automation solution.

Simple, robust, affordable - these are the attributes of the ByCut Eco. The new Bystronic ByCut Eco 3015/4020 with a choice of 3, 4 or 6 kilowatts of laser power is the right choice for entrepreneurs who want to get into the laser cutting business or want an uncomplicated fiber laser without many extras.The ByLoader Flex is the ideal automation system for handling sheet metal on a Bystronic laser cutting system. If customers have more than one laser cutting system, the "2-for-1 principle" of the ByLoader Flex is the perfect solution: a single automation system serves two laser cutting systems. Two laser machines can be managed simultaneously with one ByLoader Flex.

The simple operation and low price are the plus points of this cutting cell. Customers can leave the loading and unloading process to it and take care of more important tasks.

"Laser Packages"

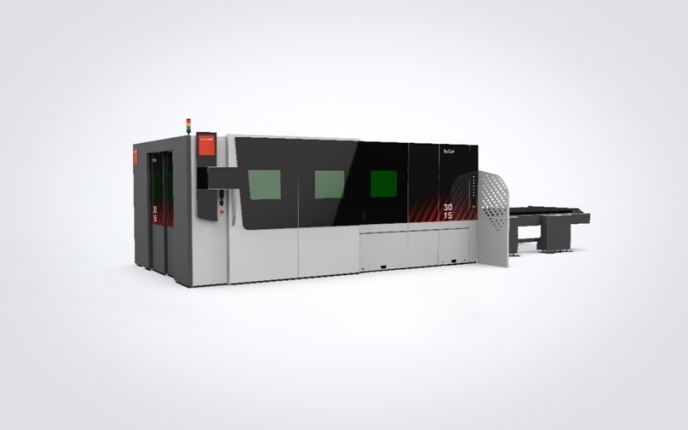

Bystronic is taking a new approach for the future of its laser cutting systems: Customers no longer select predefined machines in various classes with existing features, but instead assemble their Bystronic laser cutting system themselves according to their production requirements.

The proven ByCut laser cutter forms the basis. Depending on requirements, an Autonomy Package, a Power Package, a Dynamic Package, a Quality Cut Package or a Convenience Package are added. This means that customers receive exactly what they really need. The packages can also be combined.

The laser cutting cell with laser packages on show at EuroBLECH includes a complete automation system with the ByCut 30-kilowatt laser cutter, a third shuttle table (Shuttle Table Extension) and the ByTower Compact combined loading and unloading system including storage tower.

Bending novelty

The next generation of bending technology: clean and highly efficient bending of sheet metal thanks to compact dimensions and an electric drive - that is the new ByBend Smart E with its clever features. It provides Bystronic customers with another pioneering machine to keep them ahead of the competition.

The next generation of bending technology: clean and highly efficient bending of sheet metal thanks to compact dimensions and an electric drive - that is the new ByBend Smart E with its clever features. It provides Bystronic customers with another pioneering machine to keep them ahead of the competition.With the impressive bending capacity of 350 or even 550 kilonewtons (kN), which corresponds to a press force of 35.7 or 56.1 tons respectively, users in the sheet metal working industry reduce the cycle time in their production and thus increase productivity.

In times when sustainability is a top priority, new machines with better energy consumption have an advantage. The ByBend Smart E also scores here: thanks to the intelligent electric drive, energy consumption can be significantly reduced.

Software

With the BySoft Suite, customers digitize their sheet metal processing business from quotation preparation to delivery of the end product. The software developed specifically for the sheet metal processing industry won the EuroBLECH Award in the "Handling and Automation" category at EuroBLECH 2022 and has since become a model for success. Whether with individual modules for the respective application area, the "Digital Plans", the "Digital Solutions" or the entire package for the complete digitalization of production: the BySoft Suite optimizes and accelerates the sheet metal working process.

With the BySoft Suite, customers digitize their sheet metal processing business from quotation preparation to delivery of the end product. The software developed specifically for the sheet metal processing industry won the EuroBLECH Award in the "Handling and Automation" category at EuroBLECH 2022 and has since become a model for success. Whether with individual modules for the respective application area, the "Digital Plans", the "Digital Solutions" or the entire package for the complete digitalization of production: the BySoft Suite optimizes and accelerates the sheet metal working process.

Services

Whether laser cutting, bending, automation or software – the experienced Bystronic experts support customers throughout the entire life cycle of their systems so that they can achieve maximum performance. In every situation, customers can rely on Bystronic's expertise to meet all their requirements.

Bystronic Care plans offer a comprehensive range of services and ensure that customers have the access and support they need to get the most out of their systems and prepare for future challenges.

Bystronic also offers its customers useful digital tools such as eProActive Service or ePartsFinder, which simplify the life of sheet metal workers and extend the life of the machines.

Only the best is good enough for a Bystronic system: first-class customer service tailored to the respective requirements.

Sustainability

With Bystronic systems, customers optimize their use of energy and resources and reduce CO2 emissions.

Sustainability plays a central role in Bystronic's corporate strategy. The aim is to shape a sustainable future with sheet metal. To this end, Bystronic has developed an ambitious sustainability strategy that is consistently implemented across all areas. In this way, Bystronic helps its customers to produce in a more environmentally conscious manner, save costs and reduce their footprint.

Bystronic Solution Forum

The Solution Forum is designed to inspire. It is Bystronic's keynote stage at EuroBLECH in Hanover. This is where innovation and sustainability meet. Every day, four inspiring keynotes will take place, making the future of sheet metal processing and global trends tangible.

Visitors will experience exciting customer stories first-hand, immerse themselves in the world of green steel and discover how artificial intelligence and the industrial metaverse are revolutionizing the industry. Customers, experts and partners share their visions for a sustainable future and show how state-of-the-art technologies are driving the industry forward.

The forum is more than just a stage – it is a meeting place for innovators and future shapers.

With Bystronic, customers can concentrate on their business, while Bystronic takes care of the further development of the manufacturing process and the digitalization of the company.

Bystronic's laser cutting, bending and automation solutions and industry-leading software suite help customers achieve unrivaled productivity and support them with world-class service.

Each solution is tailored to the respective needs, which are as unique as the company itself.

About Bystronic

Bystronic is one of the world's leading technology companies in the field of sheet metal processing. The focus is on the automation of the entire material and data flow in the cutting and bending process chain. The intelligent networking of laser cutting systems and press brakes with innovative automation, software and service solutions is the key to the comprehensive digitalization of the sheet metal industry.Bystronic's headquarters are located in Niederönz, Switzerland. Other development and production sites are located in Sulgen (Switzerland), Gotha (Germany), Cazzago San Martino and San Giuliano Milanese (Italy), Tianjin, Shanghai and Shenzhen (China) and Hoffman Estates (USA). We are active in over 30 countries with our own sales and service companies and are represented by agents in numerous other countries. Bystronic AG is listed on the SIX Swiss Exchange (SIX: BYS).

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2024 Press release

EuroBLECH 2024 Press releaseBystronic at EuroBLECH 2024: "Solutions as unique as your business"

Published on 16/10/24