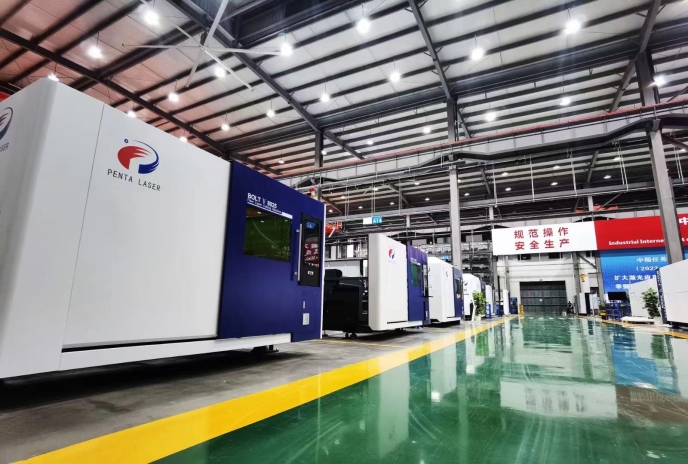

Penta Laser is a fiber laser machine manufacturer with about 30 years experiences in laser machine application. Penta Laser has core technologies in both manufacturing advanced high power laser machine and CNC machinery integration with high compatibility. Adhering to its operation philosophy of “Being Laser Application Expert, Creating Value for Customer”, Penta Laser obtained around 100 laser patents and developed a series of laser equipment at international advanced level, all these advanced laser equipment are award winners and have been widely applied in machinery manufacturing, locomotive fabrication, aerospace, and sheet-metal production.

In 2019, Penta Laser succeeded in developing the first 20KW ultra high power intelligent laser cutting machine in China that fills domestic technical gap of such power level and greatly increases benefit for more customers, and then 30kw, now 40kw. The high power machine installed complete new CNC that reacts and moves reacts in microseconds and allows to perform extremely advance functions; equipped with specialized high-power laser cutting head, to ensure the machine a long-time running with efficiency and stability; auto-focus and rapid perforation, unique 360° anti-collision, shining cutting, sharp Angle cutting and precision cutting technology, make it a precision parts manufacturing tools.

Through all these years, Penta Laser has insisted on its quality policy of “Stay Meticulous, Maintain Persistence, Put Quality First, Continue Innovation, Serve with High Quality, and Keep Every Word” all along. We are looking forward to leading technological reform in laser application together with you.

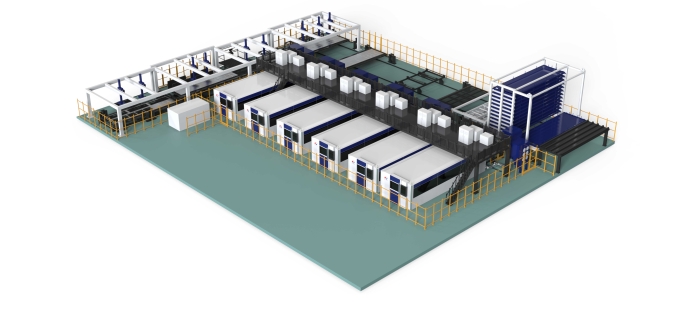

Penta Laser Automatic Production Line Loading and Unloading System

Penta Laser smart laser cutting production line include large-scale warehouse+intelligent convey system+laser cutting + intelligent sorting system, it realize automatic and unloading, automatic convey, automatic sorting, build an intelligent control of the whole production process from production plan to the final products be finished. Each machine, each unit and each system can be operated by manual when the system can not run automatically because of a failure or any other reasons.

This system can realize plate storage, automatic delivery, automatic pick up, automatic loading and etc. This fully automated production process can ensure the product quality, improve production efficiency and reduce production cost.

The convey system is driven by frequency conversion motor and can be continuously variable transmission to meet the requirement of different production speed. The loading conveyor picks up the the plate from the warehouse, and sends to the cutting area through the system, then sends it to the cutting position by single deck roller conveyor. The loading sensor will feedback information to the cutting machine when it confirms that the tray reaches the cutting position. After cutting, the roller convey system will transfer the tray to the unloading conveyor, then send the tray to sorting area. After sorting, the empty tray will be sent back to the loading conveyor to realize the automatic circulation

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releasePENTA will participate in EuroBLECH2022 with high power fiber laser machine

Published on 14/09/22