Our passion is to build success and create products that provide real solutions for the Steel Processing industries. Automation, Quality, and Customer Service are our primary values, reflected in all that we do.

Voortman Steel Machinery has been designing and developing CNC-controlled machines and solutions for the steel fabrication and manufacturing industry for 50 years. With more than 250 dedicated employees, we are continuously developing while providing an optimal experience in order to meet your needs in the best possible way!

We want our machines to be user-friendly, long-lasting, and reliable. Because your experience needs to be the best it can be. In a long-term partnership, we keep supporting you as you work toward your goals. Known for our customer service, we have multiple international offices and warehouses to keep us close and local.

Wherever you are, we’re there for you.

Fastest drilling, milling and layout marking machine out there; The V633

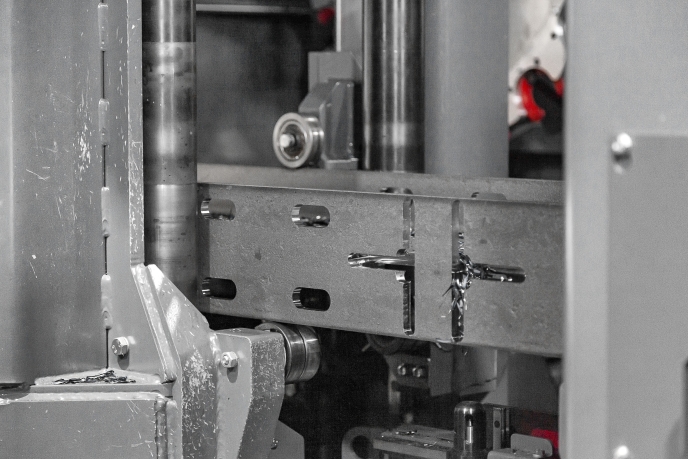

During the exhibition we will introduce you to the fastest drilling, milling and layout marking machine in the world! Four sub-axes enable simultaneously drill and mill on three sides, plus marking on four sides. The innovative solid build makes the machine truly stands out in the industry. The design emphasis is based on strength and product quality, impressing all who have seen it in action.

This machine is made to deliver quality. The machine can easily handle the powerful forces coming from the three drilling units. Everything within this machine is subservient to consistent quality, such as accurate measuring systems, short tool lengths and a very rigid sturdy box frame. Even when milling three sides of your material in one pass, and at the same time, the quality is real.

The exterior of this great machine will be completely transparent, so that the efficiency on the inside can also be seen. Camera feeds will show real-time operations on a screen. Be impressed!

The first automated plate sorting solution; the Voortman Plate Sorter

The NEW Voortman Plate Sorter will change your entire logistical routing of plate parts to your welding area, with maximum efficiency as a result. The days of sorting plate parts at the machine, missing parts at the welding area, and a complete chaos at your plate and welding area are over.

From now on you can nest and utilize your plates to the fullest. Multiple phases and projects can be nested together in one plate, increasing your efficiency and reducing your material costs. Is the whole plate processed? Simply unload the finished parts from the cutting table, put them unsorted in a bin and move it to the Voortman Plate Sorter. It will do the rest!

It scans and identifies the plates, checks their quality, sorts them into the right bin and stores them in a storage tower. It's that easy!

Creating ready parts with our multi-processing solutions

Optimizing and streamlining your logistics process also is a core part of our multi-processing philosophy. Lean on Voortman's multi-processing machines in order to create a cost-efficient, flexible and streamlined production process.

There's no need for moving or dividing material across different work stations anymore, resulting in less transport and intermediate stock in your workshop. For instance, the Voortman V633 enables you to simultaneously drill holes and mark, but also mill up to a diameter of 20mm in one powerful pass, all on one single machine!

Additionally, the new pipe cutting unit extends your processing capabilities and reduces logistical movements through your factory, since the unit is placed directly next to the Voortman V303 or V310 plate processing machine.

I am impressed! How can we get in touch with eachother?

You should come and participate in various demos of the Voortman V310 plate processing machine and the Voortman V633 beam drilling and milling machine with four sub-axes. Discuss our vision for multi-processing. Meet our latest machines and be inspired. The Voortman Plate Sorter and the Voortman Pipe Cutting Unit will be presented to you for the first time at EuroBLECH.

A fresh cappuccino and tasty Dutch specialty will be waiting for you at the booth. Come talk to machines and people and we will be happy to help you.If you need any additional information after EuroBLECH you can visit our website at www.voortman.net

See you there!

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseCome talk to machines and people at Voortman Steel Machinery at EuroBLECH

Published on 15/09/22